Creation of USTEK: As RFID technology gained popularity in asset management, tracking goods, and inventory, it became clear that it would be invaluable in the laundry industry to enhance efficiency and eliminate tasks like manual counts and order validation. USTEK was founded to introduce RFID technology to our family-owned PAK Laundry.

About Us

Our journey as USTEK began in 2006 when our family-owned and operated laundry facility, PAK Laundry, needed a system to efficiently track, pack and sort the linen coming through their doors every day. We quickly realized that RFID technology was going to be the answer and got to work.

By 2007, Pak Laundry became the first 100% UHF RFID laundry facility in the world. Since then we have helped convert countless laundries to efficient RFID-enabled systems and brought many in the hospitality and medical industries up-to-date. Our products are making a difference in over 30 countries around the world.

What sets us apart?

Vertical Integration:

We are a vertically integrated company. Every component of our solution is expertly developed in-house from the design and manufacturing of the RFID tags and the readers used for tracking inventory to the software solutions to manage your entire operation.

Continuous Field-Testing:

All of our solutions are utilized at our own laundry facility so we know we have the best product for you. We make the best product because we need the best product for our own operations. The continuous field-testing allows us to track the performance of our systems and provide feedback to our engineers that in turn enhance our products.

Always evolving:

We constantly track and experiment with new technologies that can be applied to our projects, we continuously develop and update new software modules to answer upcoming client needs and we are open to cooperate with clients to customize or develop new products that would enrich our portfolio.

A Brief History of USTEK

-

2006

-

2007

Pak Laundry: Became the world’s first 100% UHF RFID Laundry facility. The adoption of RFID led to a fivefold increase in production over 10 years, automating processes like inventory tracking, stock movement, order creation, and cost analysis.

-

2010

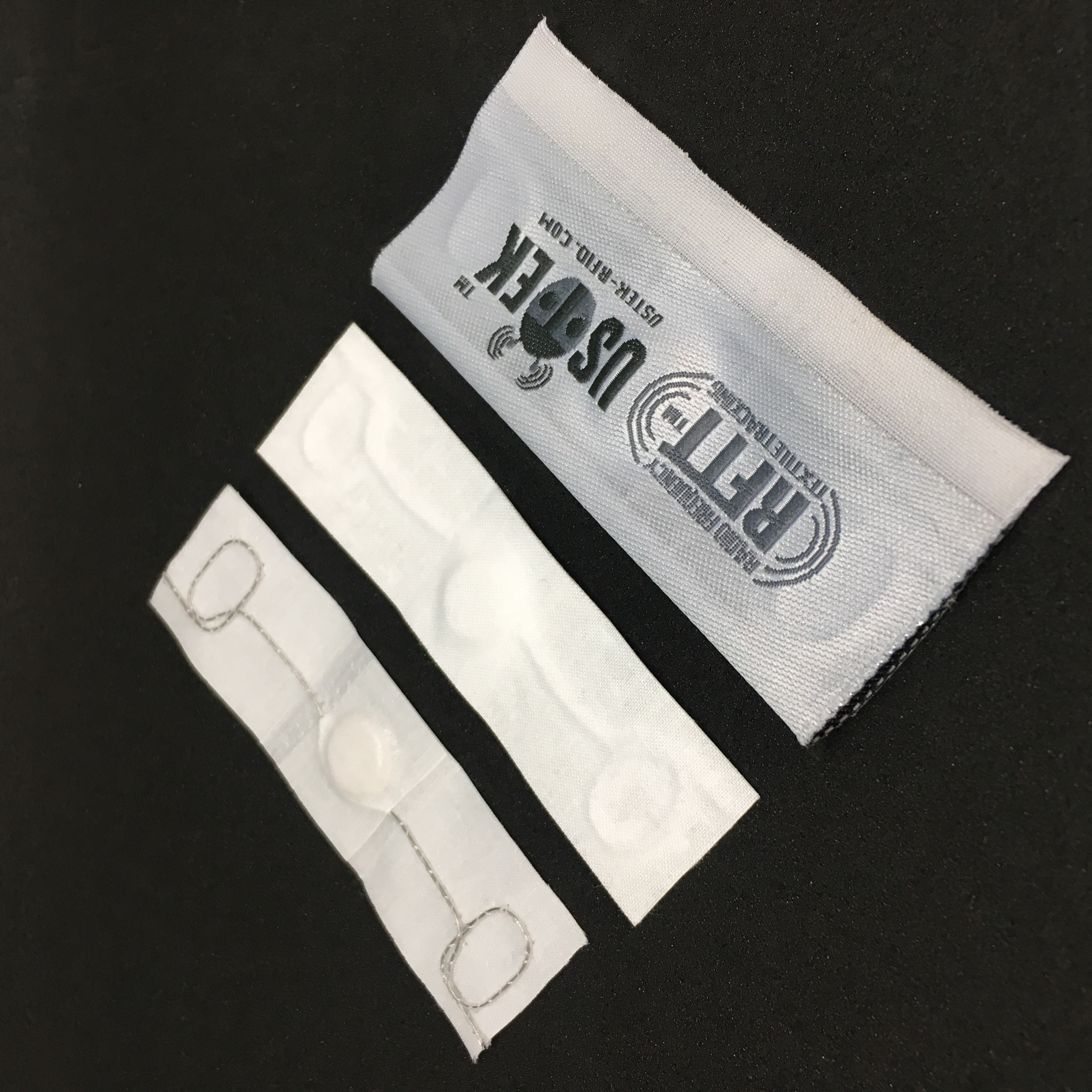

The first generation USTag70 was created: Built on Impinj RFID tag chips, USTEK optimized laundry tag design for industrial durability and reading accuracy. Available in heat-sealable, sewn-in, and woven formats, our tags continue to evolve alongside Impinj advancements.

-

2010

First European Showcase at Expodetergo - Milan: USTEK expanded into Europe, demonstrating RFID applications in commercial laundries and how our tags, hardware, and software integrate for seamless operations.

-

2017

Clean Show - Las Vegas: USTEK connected with US business owners, sharing expertise from our own transition to RFID technology at PAK Laundry, guiding businesses through the adoption process.

-

2018

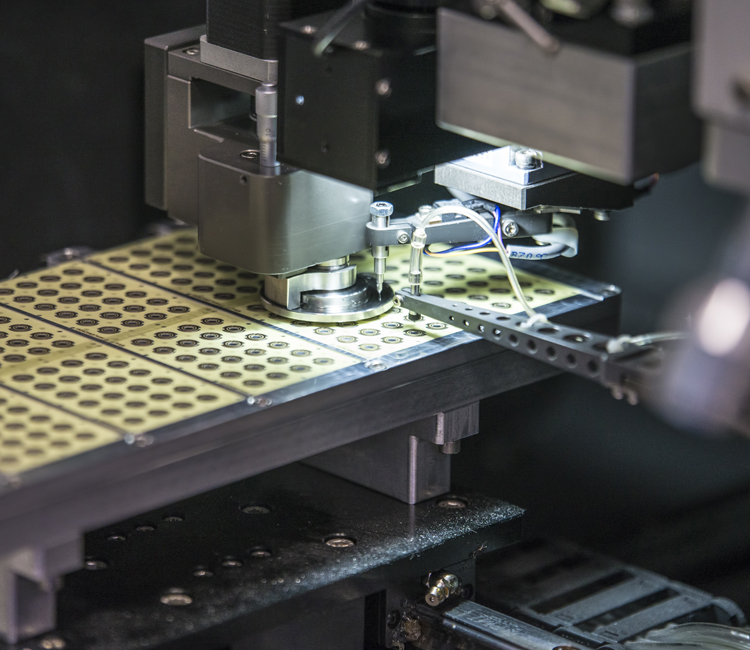

Expansion of Production: In-house semi conductor chip on board capacity tripled through a major expansion of cleanroom production space.

-

2020

First European Branch: Established in the Netherlands, this branch serves our growing European clientele, complementing our distributor and sales partner network.

-

2023

Expansion to rubber tags: Leveraging our textile sector expertise, USTEK entered the rubber tracking sector with the USTAG-ER72. The tag’s antenna is optimized for rubber materials and can be customized for specific frequency ranges.

-

2023

First US Branch: Our Boston, Massachusetts area branch supports our growing US market presence, offering 24/7 support across time zones with expertise tailored to local market needs.

-

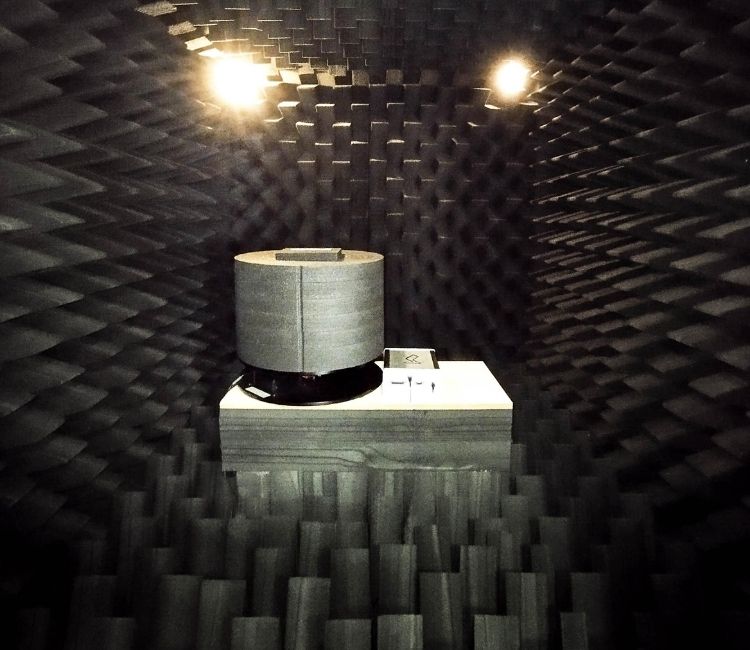

2024

In-house Anechoic Chamber Installation: The chamber enables USTEK to conduct in-house testing for superior product performance, supporting product development and design optimization.